Catalyst Recovery Filters

Consistent, Clarity, Robust, Repeatable Backwashing

G Squared is your Gulf Coast area expert for process filtration solutions including catalyst recovery filters. Our Mott HyPulse® filtration systems and elements provide superior solutions for high-temperatures and harsh environments. Additional benefits include:

- Uniform, high-precision porous metal media

- Long service life

- Discharge solids as a wet cake or concentrated slurry

- Blowback (gas) or backwash (liquid) cleaning provides operational flexibility

- Self contained design limits exposure to atmosphere and personnel

- Minimized waste generation

- No moving parts = Minimal maintenance

- Highly effective single-stage filtration

- Wide selection of materials available

Committed to Excellent Outcomes and Verifiable Performance

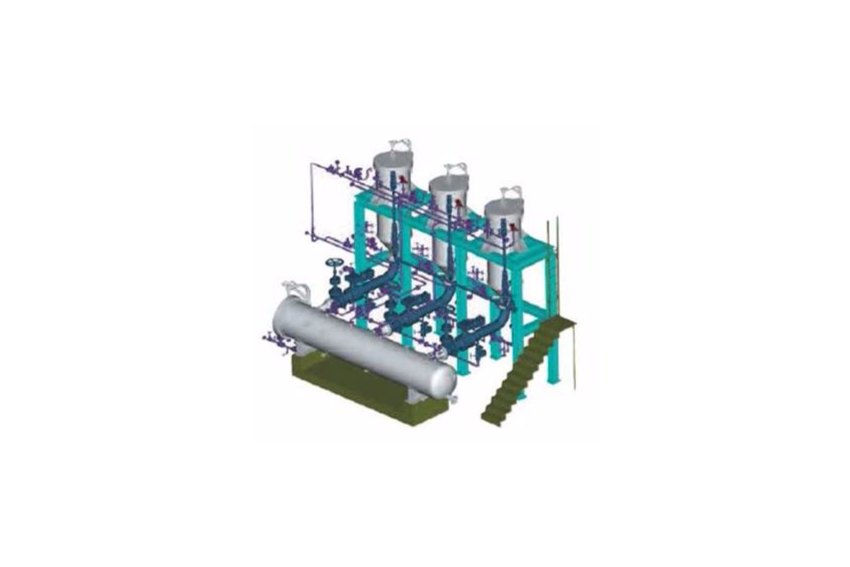

We are proud to partner with Mott Corporation to provide dependable solutions for your process filtration operations. Advantages G Squared offers you as your Gulf Coast catalyst recovery filter supplier include:

- Integrated to your upstream and downstream operations in the process

- Lab testing and pilot testing to verify performance up front, excellent scale up

- Large installation base for catalyst recovery filtration service

The G Squared team offers you the best combination of performance, quality, and value to assure the long-term efficiency and reliability of your process. Contact G Squared to discuss your catalyst recovery filters needs.

- Gas Process

- Liquid Process

- Inline Metal Filters

- Sintered Porous Metal Filter Elements

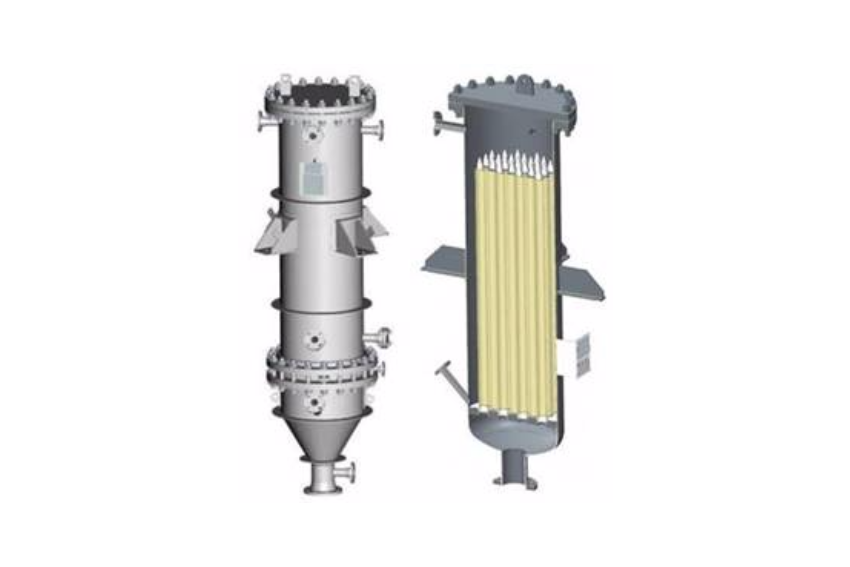

Mott gas-solids industrial filtration systems can eliminate greater than 99.999% of all solids with gas blowback cleaning. Ideal for high-temperature intensive gas processes.

Applications

- Removing contaminants from oxygen

- Rust and pipe scale removal from steam

- Recovery of polyethylene solids

- Magnesium oxide solids

- Fluid bed reactors off gas and solids recycle/recovery

- FCC 3rd and 4th stage separators

- Gasification of fuels, chemicals, and power

Markets

- Chemical Processing

- Petroleum Refining

- Power Generation

Mott HyPulse® liquid process filtration technology uses sintered porous metal tubes to deliver high clarity liquid filtration with a robust and repeatable backwash of retained solids.

Applications

- Valuable catalyst recovery, such as carbon-based precious metal, slurry oil, activated carbon, organic salts, Raney nickel, copper chromite, and other catalyst recovery applications.

- High temperature, corrosive fluids

- Contained processing of flammable and hazardous chemicals

- Radioactive waste

- Batch and Continuous processes

Markets

- Chemical Processing

- Petroleum Refining

- Power Generation

- Alternative Fuels Production

The 7710 Series HyPulse HyLine Inline Metal Filter is a dependable filter system for separating solids from liquids or gases. Standard 316 stainless steel housings and with a Buna N housing seals provide strength and reliability.

Applications

- Backwash capability pilot testing

- Liquid or gas sampling filtration for specialty chemicals

- Polishing filtration service

Markets

- Aerospace & Defense

- Chemical Processing

- Petroleum Refining

- Power Generation

- Process Control, Monitor, & Safety

- Manufacturing Equipment

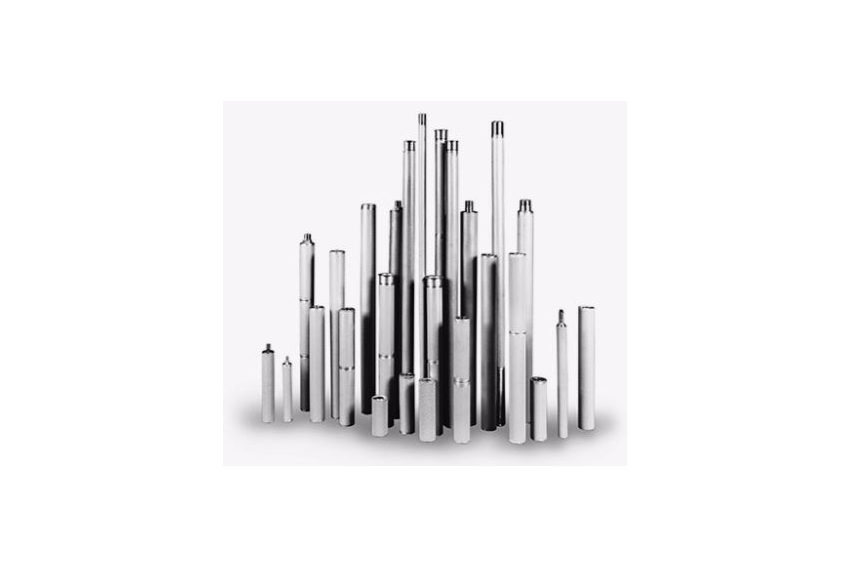

Sintered porous metal filter elements are offered in a broad range of materials, sizes, media grades, and fitting types to upgrade your current filter system with superior porous metal filtration capability.

Applications

- High-temperature liquid or gas filtration for catalyst recovery

- Corrosive chemical filtration

Markets

- Chemical Processing

- Petroleum Refining

- Power Generation

- Biopharmaceutical

- Food & Beverage