Ventilation systems are essential, particularly when used in environments that include gases that could be explosive. To ensure continuous and safe system operation, special consideration must be given when designing and specifying equipment for potentially explosive environments.

When researching equipment for potentially explosive applications and environments, it is not uncommon to hear about “explosion-proof” fans. The phrase “explosion-proof” is often used to describe fans that are designed with enclosures for electric motors and disconnect switches. The correct description is that the fan features Spark Resistant Construction (SRC). For applications in which a spark in the airstream could cause fumes or contaminants in the airstream to ignite, such as paint booths or chemical storage areas, SRC fans are essential.

The Air Movement and Control Association International (AMCA) has developed Standard 99-0401 Classifications of Spark Resistant Construction, which designates three levels for spark resistant construction: Spark A, B, and C. All three types feature a distinct way to prevent physical contact between two ferrous materials. The preferred nonferrous material used in spark resistant construction fans is aluminum, however alternative materials can also be used, such as plastics, fiberglass, and monel.

Type A SRC Fans

Providing the highest degree of spark resistance, Type A fans require all components in the airstream be constructed of a non-ferrous material. They also must be assembled in a way that minimizes the possibility of contact between any stationary and rotating component. The most common approach to meet Spark A requirement is to fabricate all of the fan’s airstream components from aluminum. These components include the housing, wheel, inlet cone and any fasteners used in the airstream. The fan shaft also must have a sheath to cover the steel, or the shaft needs to be constructed from monel. Spark A is typically the most expensive of the three spark resistant options.

Type B SRC Fans

Type B fan construction requires the impeller to be made from non-ferrous materials, and that the fan components in the airstream be assembled in a way that reduces possible contact between any stationary and rotating component. This requirement is usually met with the use of an aluminum wheel and an aluminum rub ring. In the event of a mechanical failure of the fan, the aluminum wheel will contact a steel inlet cone. As with Type C construction, the aluminum rub ring will prevent contact of the steel fan shaft and steel fan housing. In terms of pricing, Type B falls between Types A and C.

Type C SRC Fans

Type C construction offers a minimal level of spark resistance and only requires that possible contact between stationary and rotating components be reduced. This construction usually includes the use of an aluminum inlet cone and an aluminum rub ring. The aluminum inlet cone will be the initial point of fan wheel contact in the event of a mechanical failure. The aluminum rub ring placed at the opening of the housing where the shaft passes, prevents contact of the steel fan shaft and steel fan housing. Type C fans are the least expensive option.

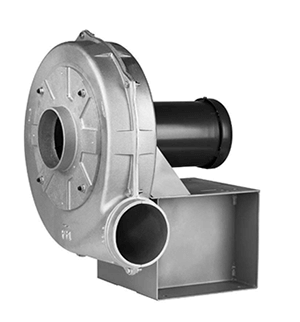

Spark resistant construction is available on many varieties of commercial and industrial blowers. In deciding which type of SRC fan construction to use, keep in mind whether the airstream will be normally hazardous or not normally hazardous. A fan that is consistently handling a hazardous airstream may require types A or B. A fan that usually handles non-hazardous gases might permit the use of construction types B or C.

G Squared is your gulf coast area source for the most dependable air movement solutions, including SRC fans designed to abate the risk of explosion in volatile environments. Contact our team to discuss your application needs.