When localized air direction for cooling and circulation are required, mancoolers provide the ideal solution. They are an excellent choice for optimizing comfort levels in high temperature work environments, cooling processes and equipment, and removing smoke or fumes.

Mancoolers also offer an efficient solution for the destratification of air to reduce energy costs. In order to select the right mancooler, you need to determine the mancooler performance you need. The CFM and/or outlet velocity should be calculated to determine this. The CFM is an indicator of air mixing capacity, and the outlet velocity is used to identify the terminal velocity at a specified distance from the fan. Downstream air velocity from the fan is dependent upon the initial outlet velocity, the fan diameter, and the distance from the fan.

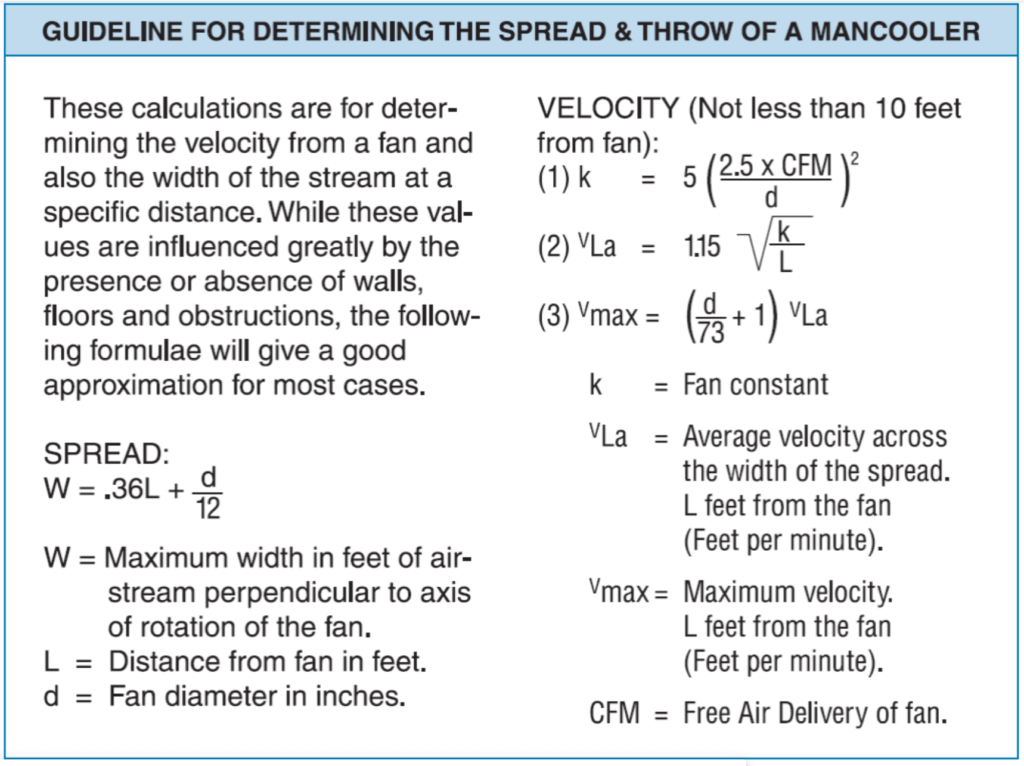

The following formula from Cincinnati Fan’s Engineering Data can be used to make the calculation:

An approximate airstream velocity used to cool personnel is 150 fpm. Lightweight items tend to move at around 170-190 fpm. Velocities over 400 fpm are too excessive for applications for cooling personnel.

Looking for cooling solutions for the employees in your facility? Talk to G Squared, the Gulf Coast area experts for industrial fan and blower solutions. We’ve developed effective and efficient air movement solutions for customers in Louisiana and Mississippi, as well as parts of Texas and Alabama. Contact us today!