In the fan industry, the term “fan start-up” can refer to two different issues. Initial fan start-up refers to the commissioning of the fan and the process of ensuring proper installation. This is important for several reasons. Poor fan installation can cause early failure, which is likely to be costly in terms of the fan itself, as well as the potential loss of production time. As with other rotating machinery, proper fan operation usually requires correct drive alignment, adequate foundation characteristics, and true fit-up to the connecting ductwork.

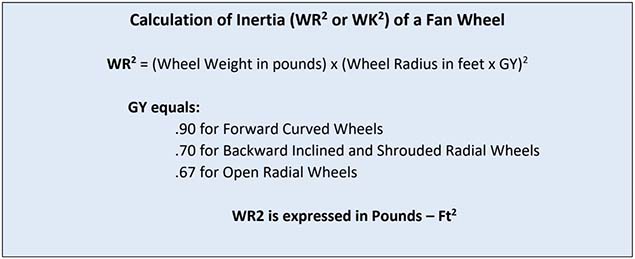

In a different context, fan start-up can refer to the acceleration of a fan from rest to normal operating speed. Many fans, particularly centrifugal types, have a large rotational inertia. This means that they require significant torque to reach operating speed.Think of inertia as being the tendency of any mass to remain at rest. Fan wheel inertia, also called WR2 or WK2, must be less than the driver (usually an electric motor) for acceleration to occur.

In addition to the WR2 load, the air mass moved by the fan also adds to the start-up torque requirements on the fan motor. Although rotational inertia is not typically a problem in heating, ventilation, and air conditioning (HVAC) applications, it may be a design consideration in large industrial applications.

Proper motor selection is essential in ensuring that the fan can be brought to its operating speed and that, once there, the motor operates efficiently.

Need assistance with determining the right fan for your application needs? Contact us to discuss your project!